Web-Based Interface (No HMI)

Headless control system built entirely as a responsive web application—no traditional HMI hardware or software. Accessible from desktop, tablet, or phone via WiFi from anywhere on site.

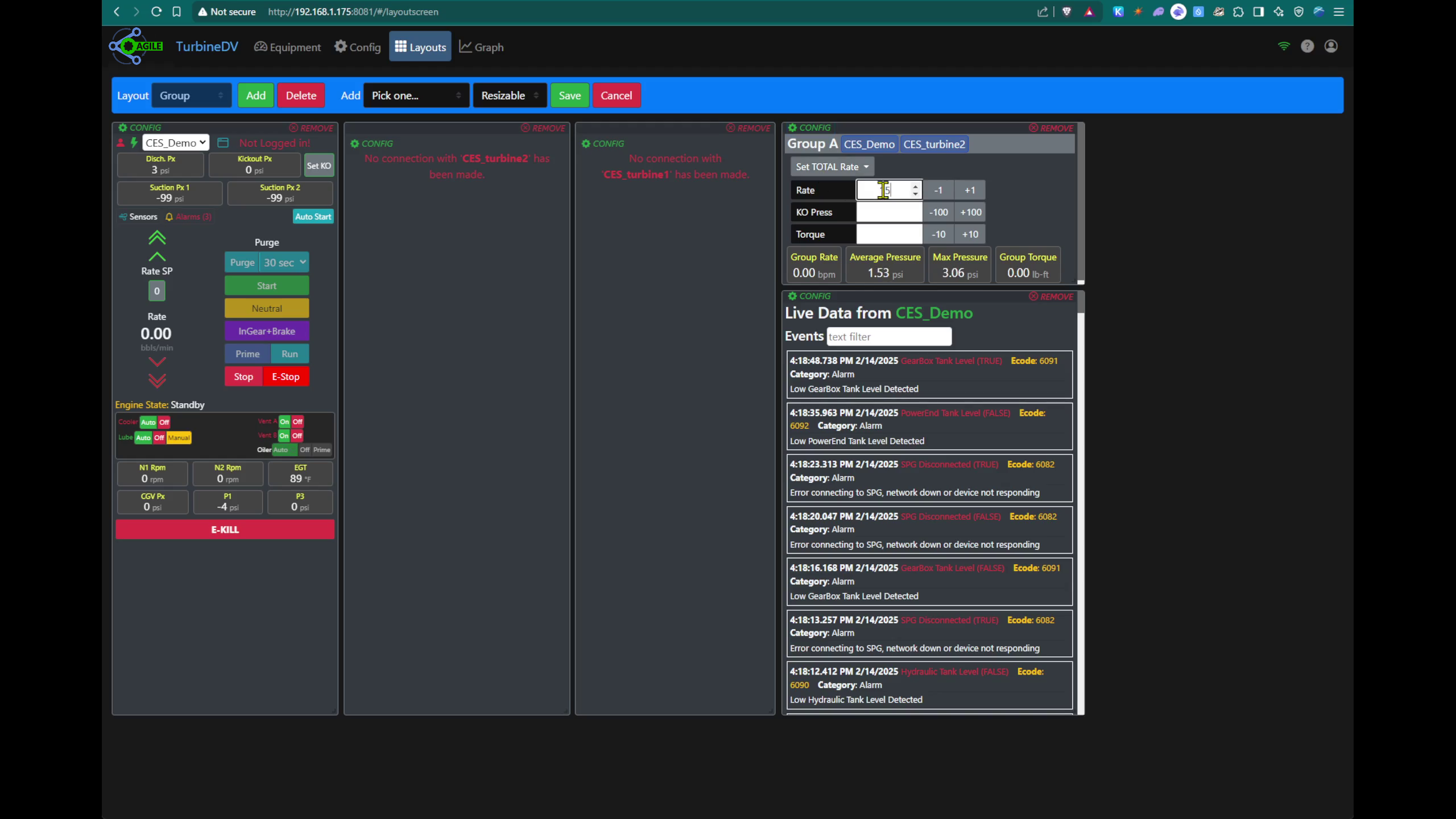

Custom web-based control application with no traditional HMI. Built entirely as a responsive web interface that integrates with GTC turbine controllers, auxiliary systems, and data acquisition. Real-time monitoring, automated safety interlocks, and comprehensive data logging accessible from any device.

Headless control system built entirely as a responsive web application—no traditional HMI hardware or software. Accessible from desktop, tablet, or phone via WiFi from anywhere on site.

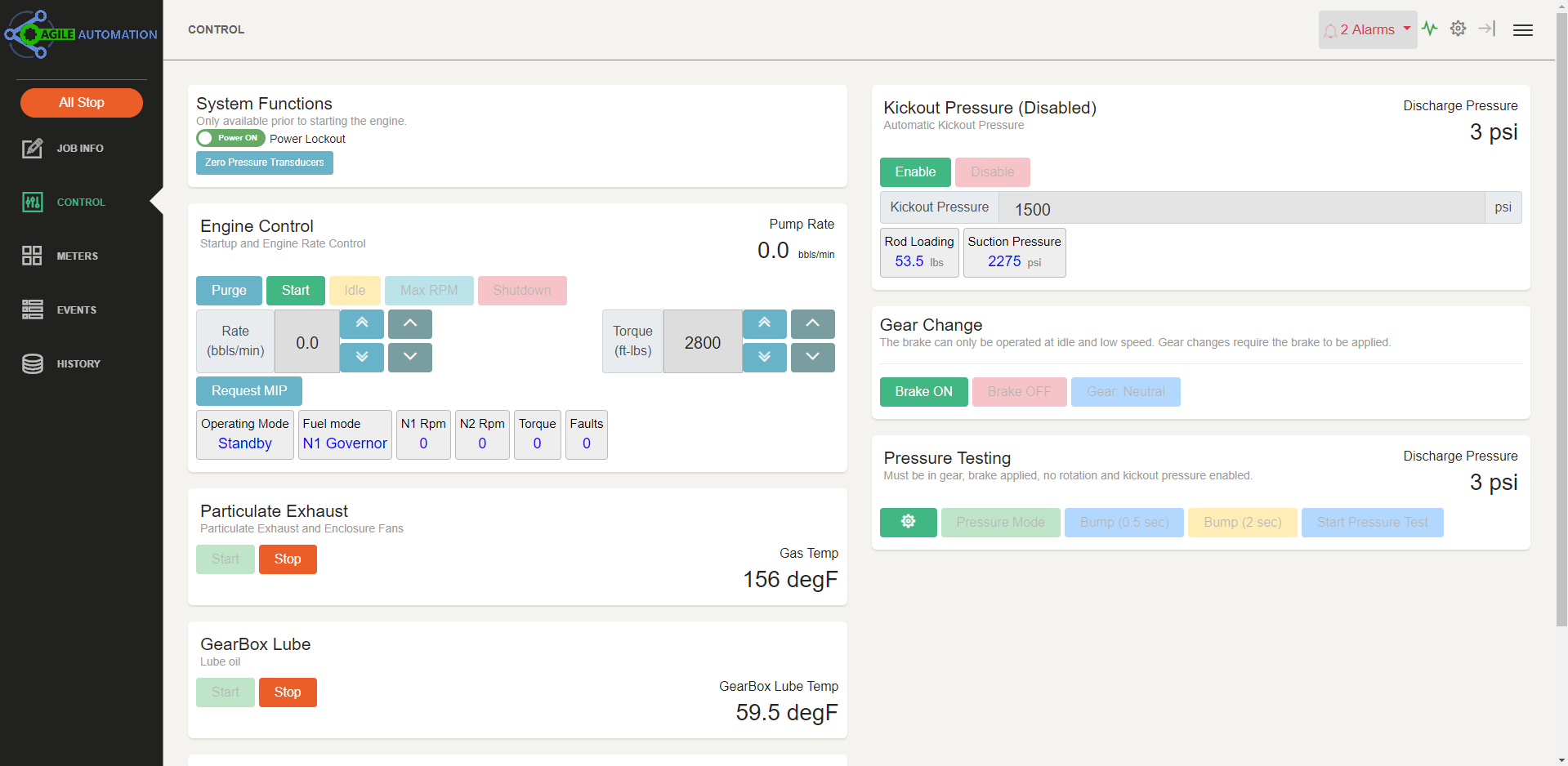

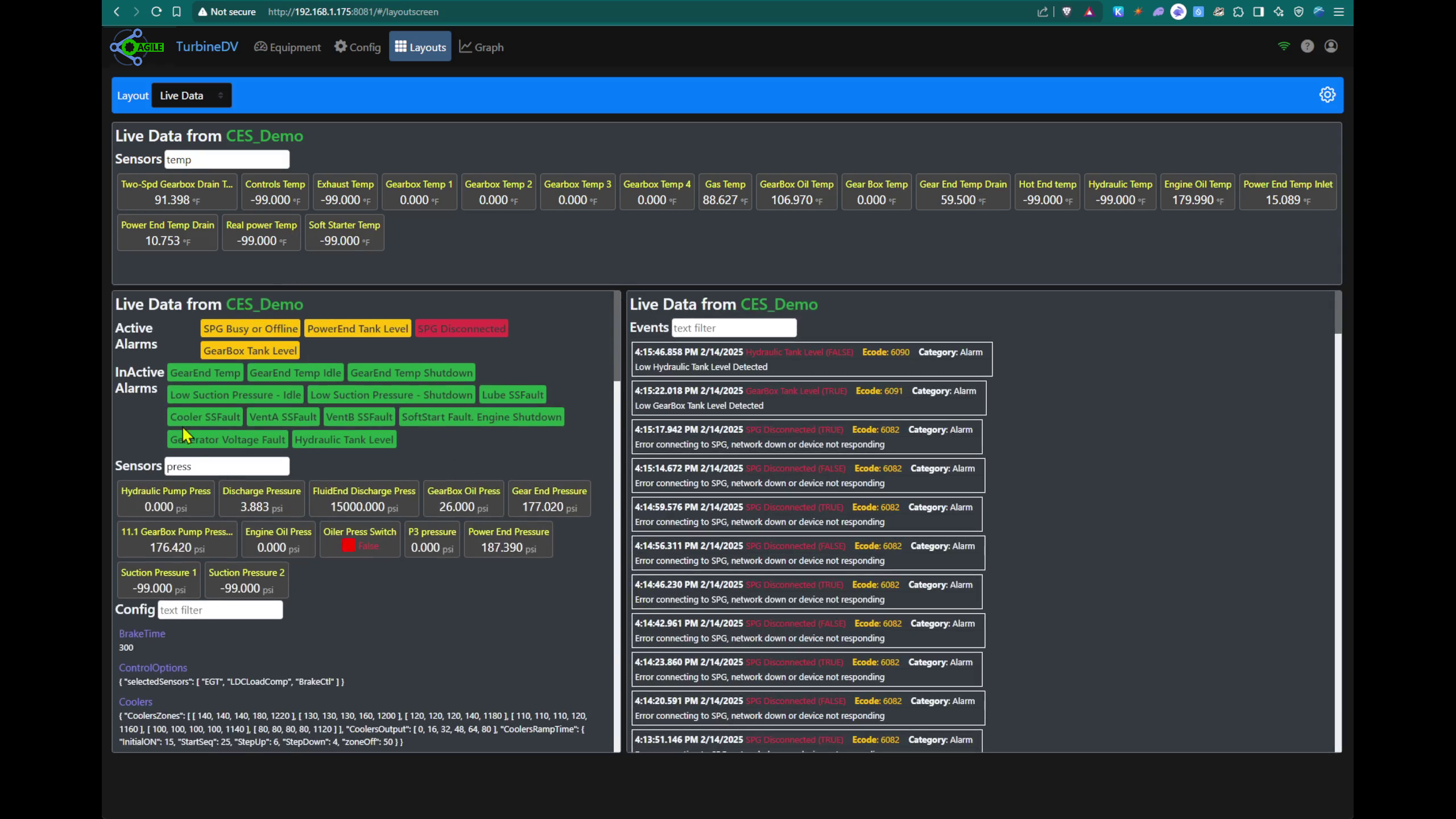

Automated safety systems monitor oil pressure, temperatures, gas leaks, and gear position. Emergency shutdown protection with comprehensive alarm management.

Direct Modbus communication with GTC turbine controller and auxiliary sensors. Real-time data collection at 10Hz with intelligent filtering and smoothing.

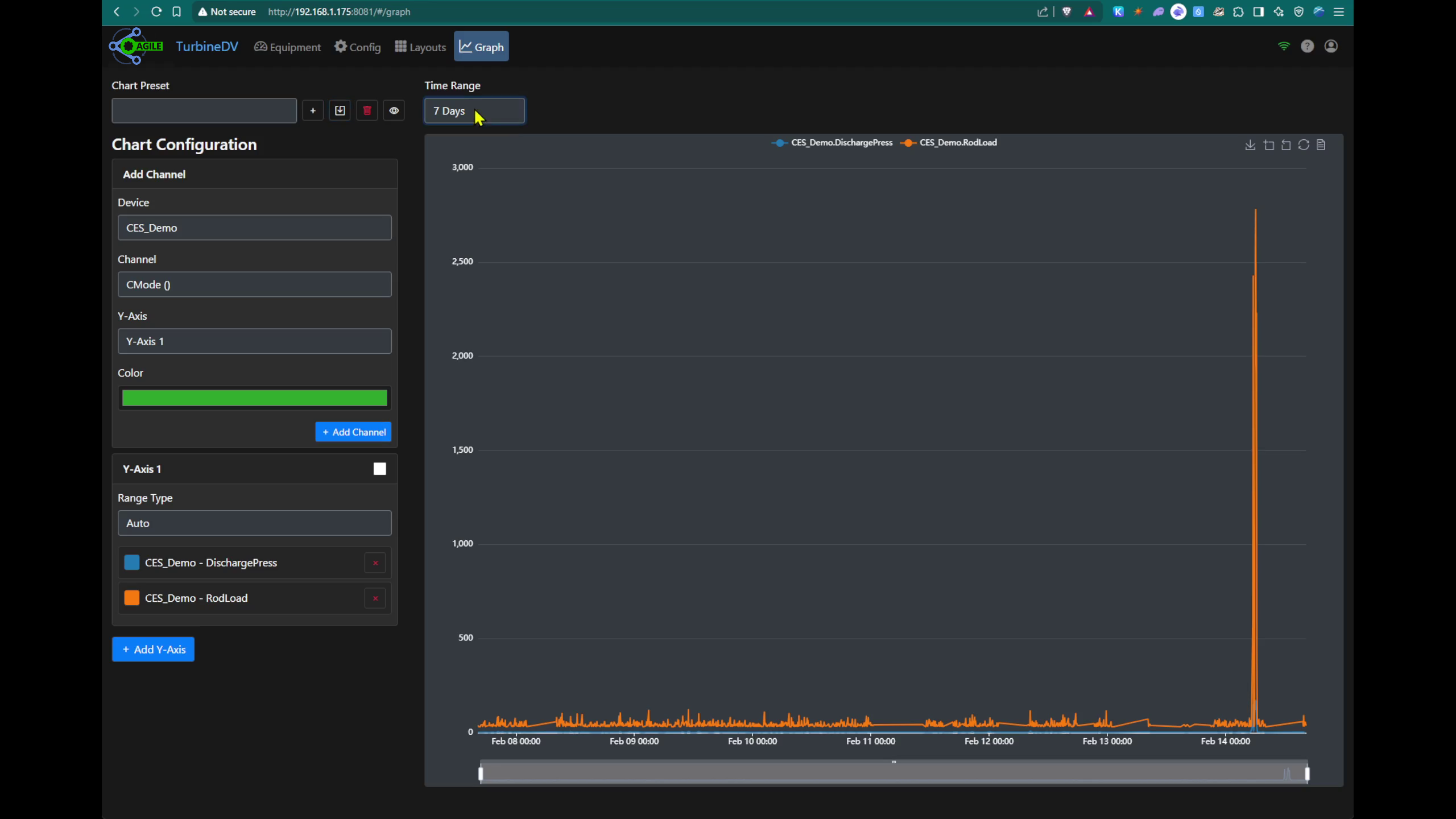

CSV data logging with continuous data, cycle statistics, and event logs. Downloadable directly from web interface with built-in viewer for troubleshooting.

Complete turbine control from a modern web interface. Monitor all critical parameters, execute startup/shutdown sequences, and manage operational modes with clear visual feedback.

Monitor all critical parameters in real-time with configurable displays. Multiple views for different operational aspects—engine, gearbox, lubrication, and auxiliary systems.

Built-in maintenance and diagnostic tools with customizable charts. View historical trends, save screenshots for records, and compare operational parameters over time.

Architecture supports multiple turbine and diesel pumps in an integrated control system. Aggregate rate control with automatic pump pool management and fuel optimization.

Optional IoT integration with AWS services for remote visibility. Live data streaming, historical analysis, and remote access capabilities.

No traditional HMI required. This custom-built turbine control system uses a pure web-based architecture with comprehensive safety interlocks, real-time monitoring, and advanced features. Designed to integrate with GTC controllers and existing equipment while eliminating the cost and complexity of industrial HMI platforms.

Discuss Your Project