DVIR and CMMS Synchronization

Automatically tie DVIR events to maintenance workflows in the existing vehicle tracking platform, so inspection issues are visible to planners and technicians without duplicate data entry.

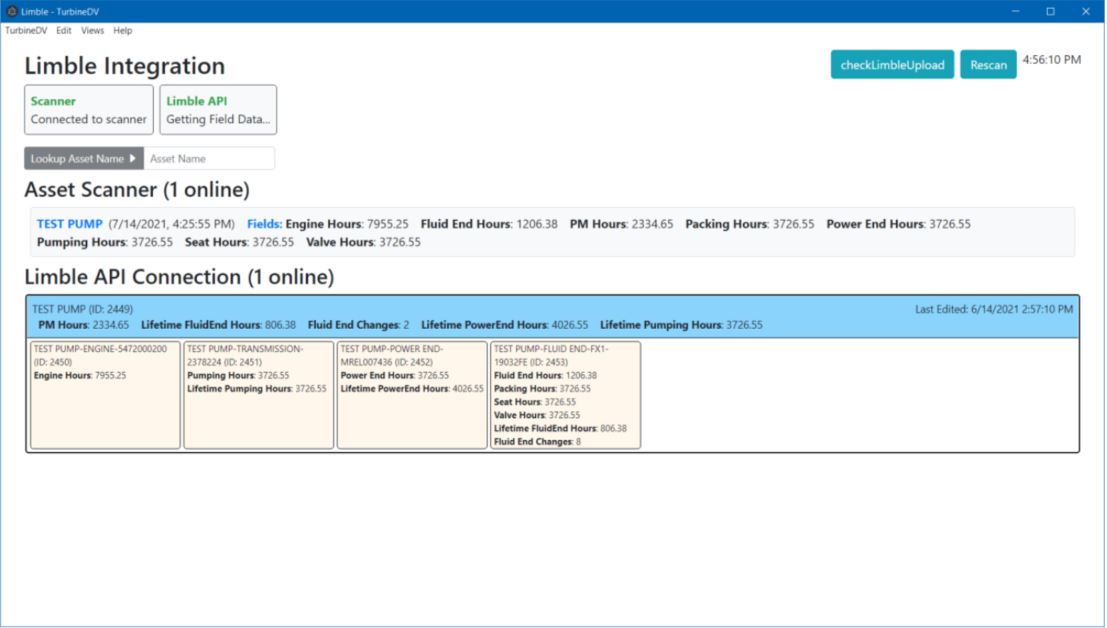

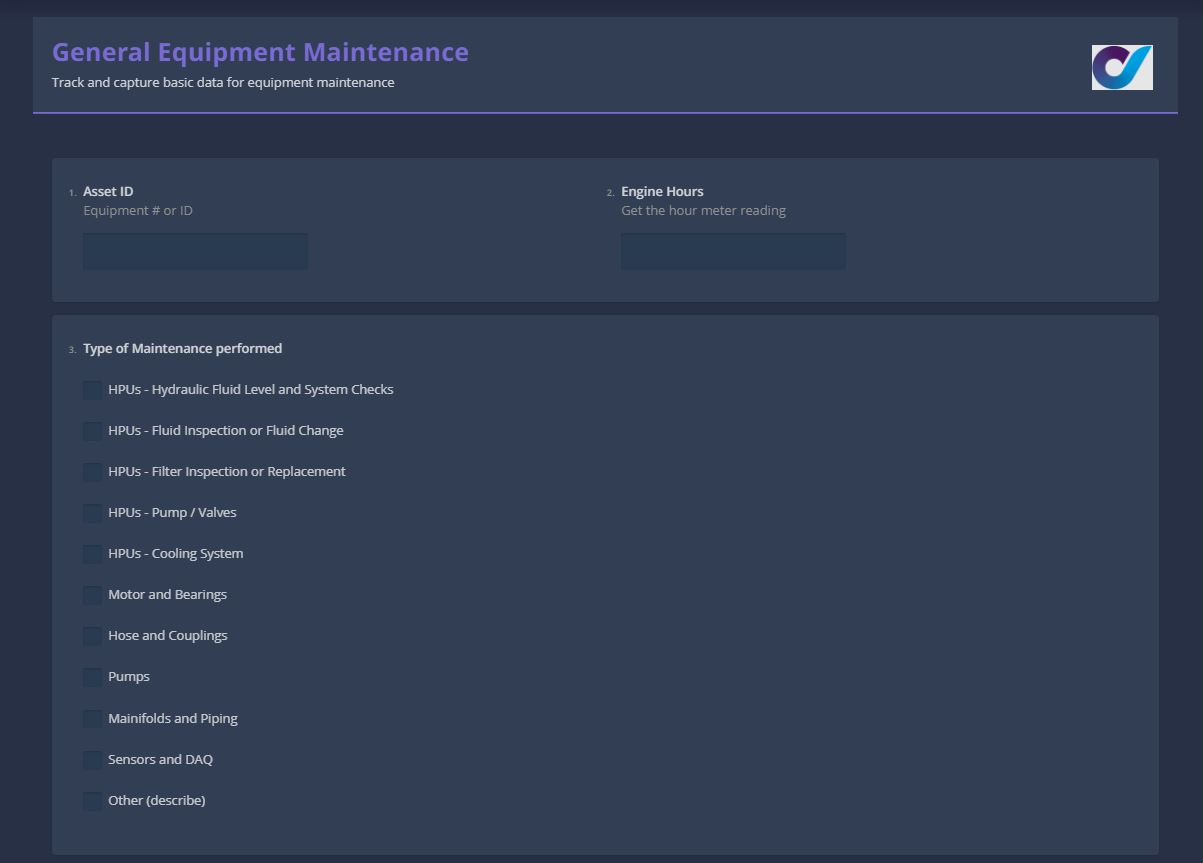

This use case integrated DVIR records, sensor data, hour meters, and maintenance logs through an API with a major CMMS vehicle tracking system. We also extended it with a synchronized database for sensor logs, maintenance events, and field actions tied to tracked equipment.

Maintenance Visibility

One system across vehicles and equipment

Operational Signals

Sensors, alarms, and runtime hours included

Service History

Clear audit trail for completed work

This approach goes beyond odometers, speed, and driver logs. We bring in field instrumentation data so your maintenance system can react to actual equipment conditions, not just vehicle movement.

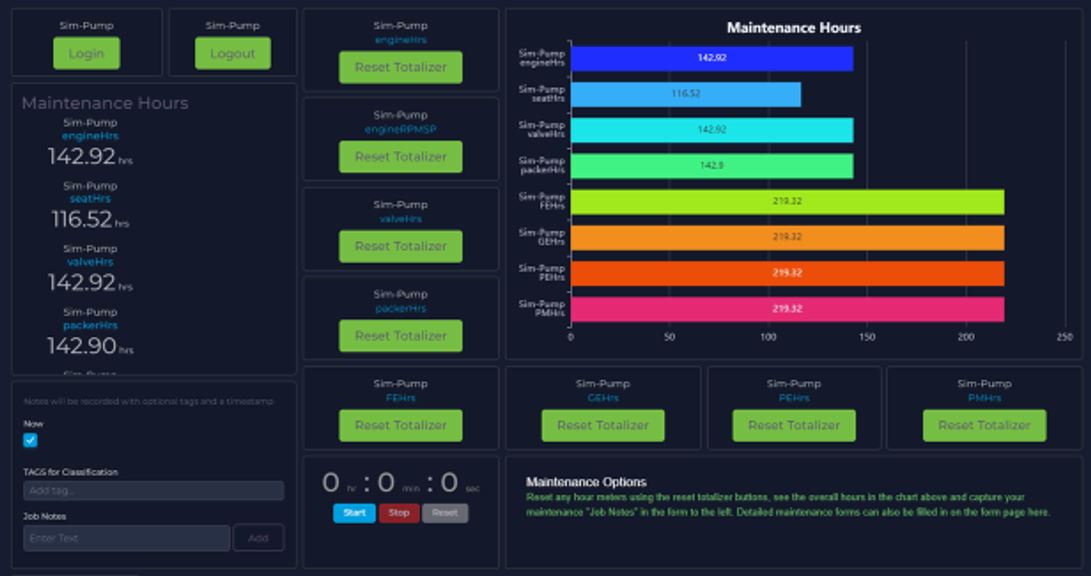

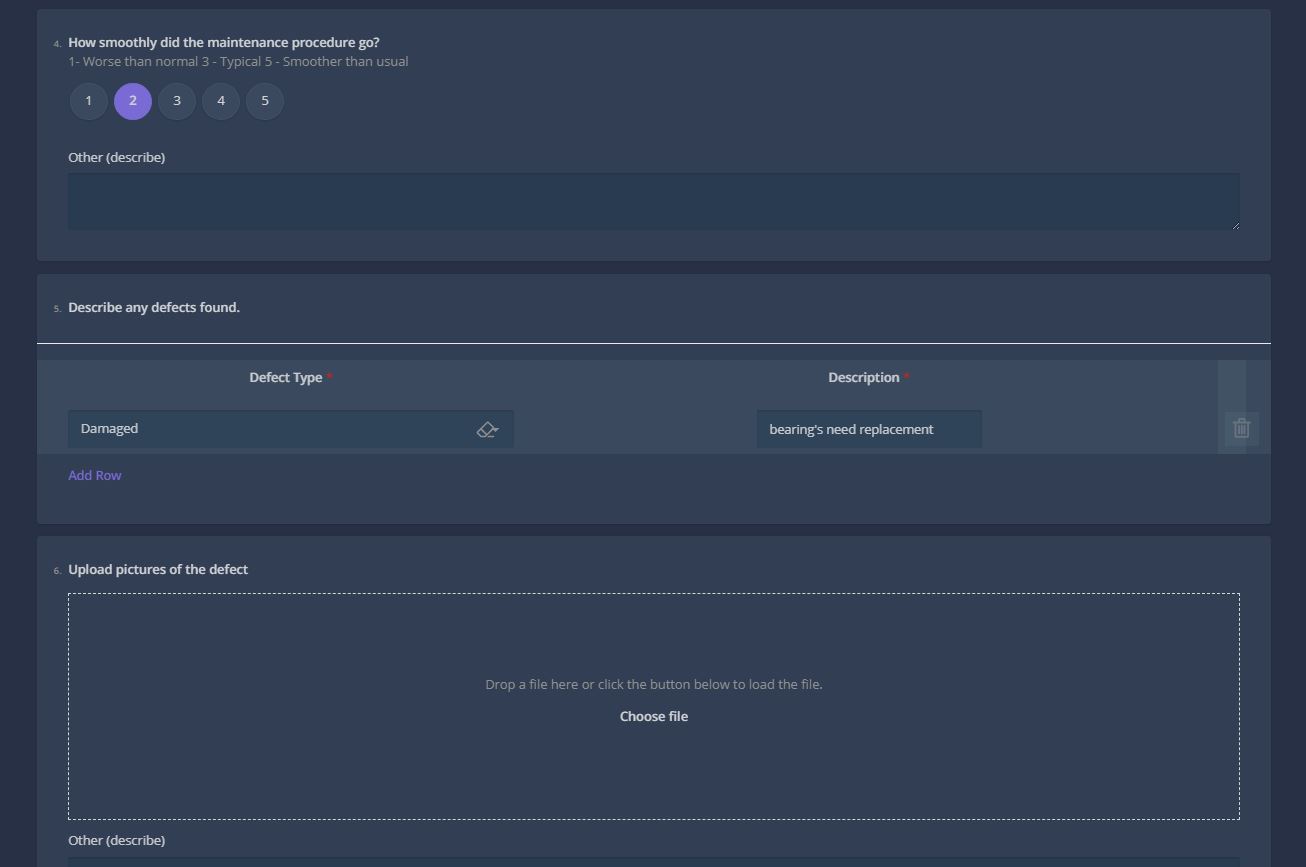

Teams can detect completed maintenance, reset equipment hour trackers after service, and record component swaps such as moving a fluid end to another asset while preserving accurate lifecycle history.

Automatically tie DVIR events to maintenance workflows in the existing vehicle tracking platform, so inspection issues are visible to planners and technicians without duplicate data entry.

Bring in runtime hours, alarm states, and equipment instrumentation channels to trigger maintenance from real operating conditions, not just fixed schedules.

Detect performed maintenance events and apply reset logic to counters and intervals, reducing missed resets and improving confidence in service timing.

Track part-level transfers such as fluid end swaps between assets while maintaining accurate meter history and maintenance lineage for each component.

Operations teams can align synced service events with live runtime data and instrumentation trends to make better maintenance decisions.

Equipment changes happen in the field and they need to be tracked right away. We've made that happen by synchronizing data between field and office. When those updates are visible to office teams, maintenance managers stay current, set up PMs on time, and create work orders with confidence.

Reliable hour and event tracking helps teams service equipment before failures interrupt operations and job schedules.

Connected DVIR and maintenance records create a stronger audit trail for inspections, customer requirements, and internal standards.

Accurate service history at both asset and component levels improves planning, extends equipment life, and supports better lifecycle cost decisions.

If your team is tracking data in multiple systems, we can unify DVIR, sensor data, hour meters, and maintenance logs into a practical workflow that supports field operations and fleet reliability.

Discuss Maintenance Integration