Hydraulic Frac Data Van

Centralized command and control for frac operations

Complete operational visibility and control from a single location. Monitor all equipment, execute automated schedules, log comprehensive data, and generate reports—all from one unified interface.

Single Control Point

All equipment, one interface

Live Operations

Instant visibility and response

Schedule Execution

Reduce manual intervention

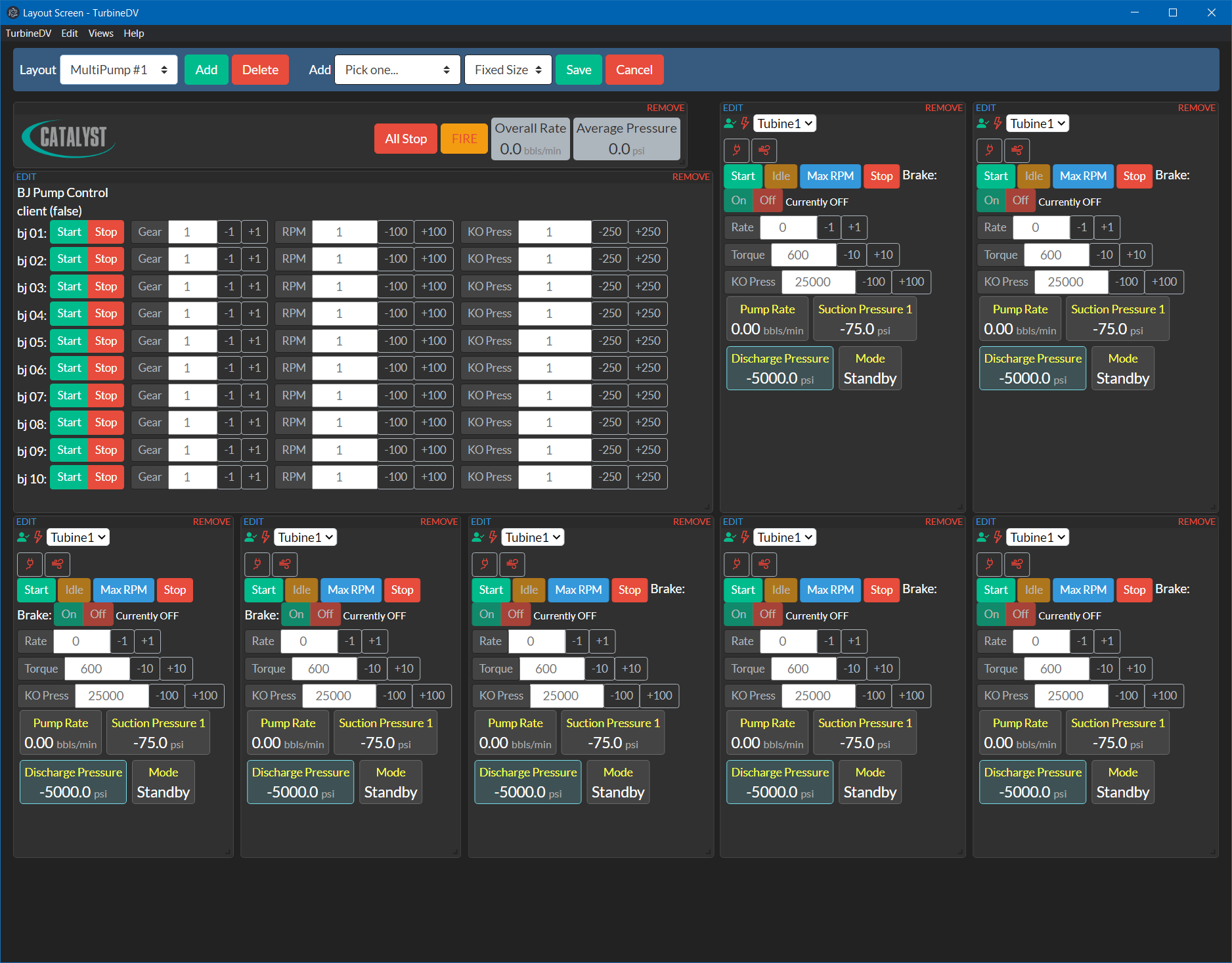

The data van serves as the operational nerve center for hydraulic fracturing jobs. It consolidates data from blenders, pumps, hydration units, and chemical systems into a single command interface.

Operators gain complete visibility, automated schedule control, comprehensive logging, and the ability to respond instantly to changing conditions—all without leaving the control station.

Core capabilities

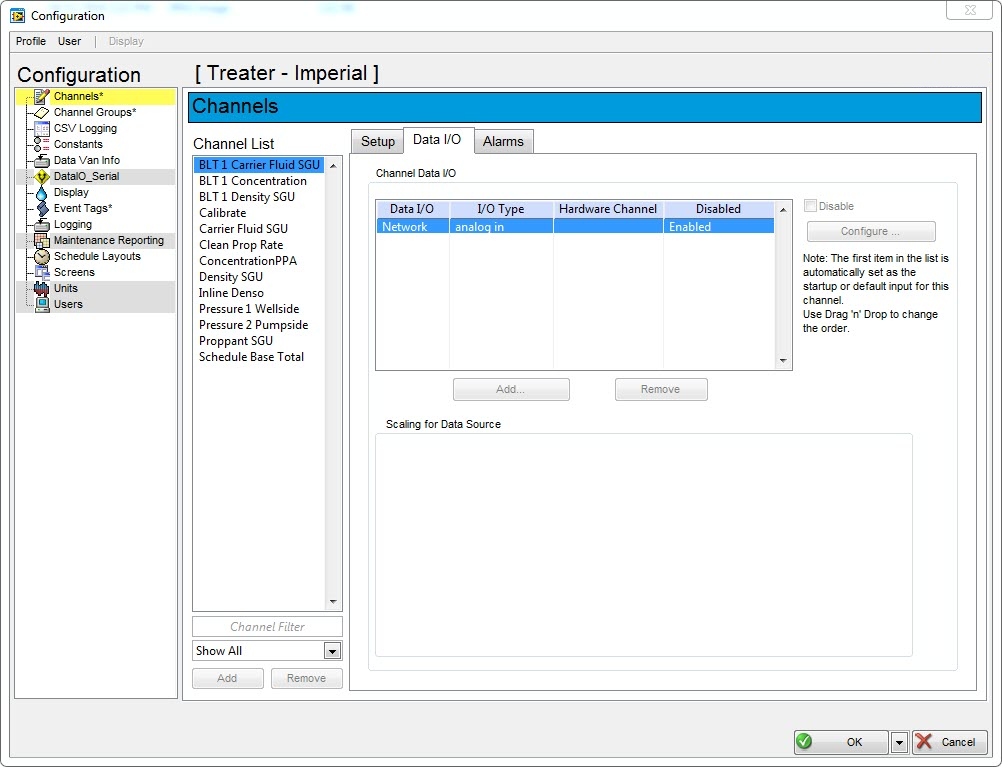

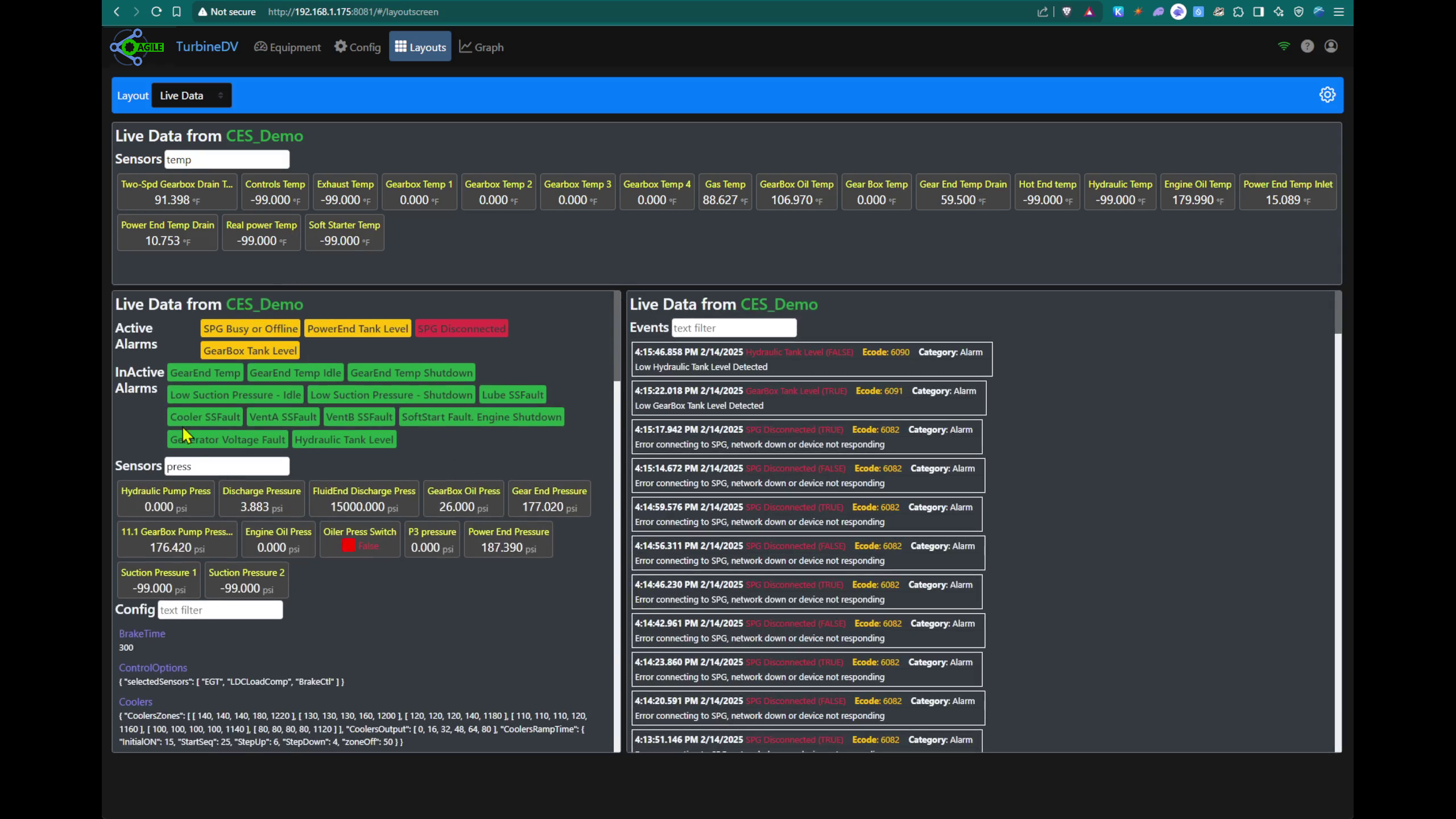

Unified Monitoring

Monitor all equipment from one location. Live meters, channel data, and equipment status for every connected system on the network.

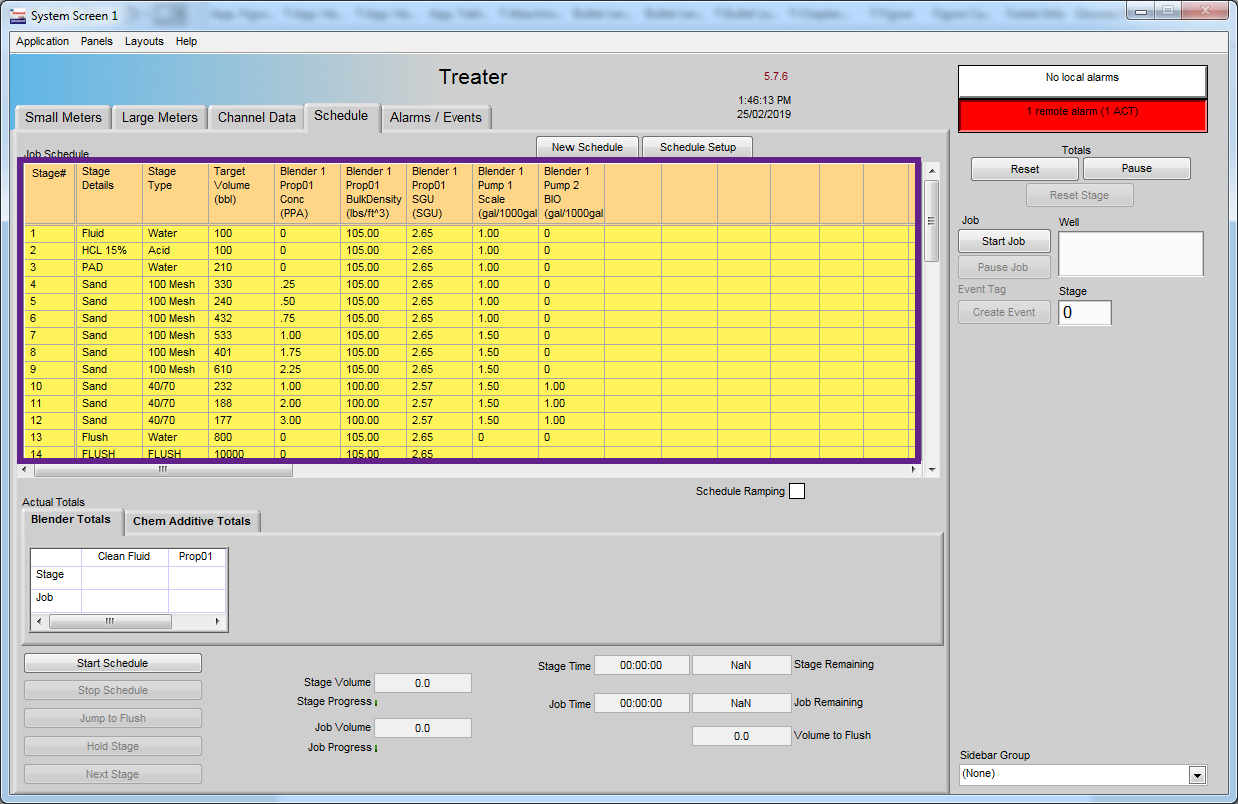

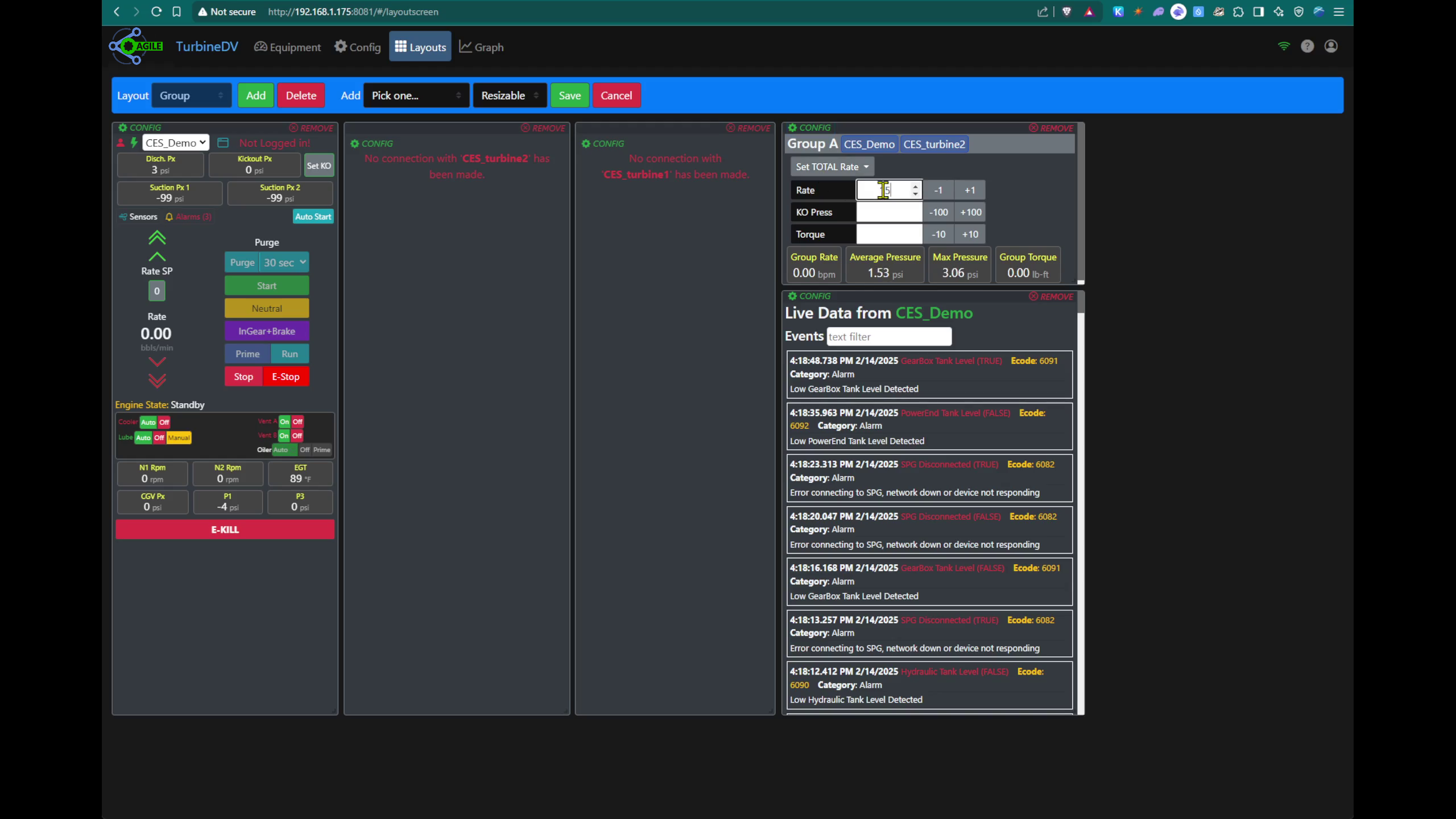

Schedule Automation

Import job schedules and execute them automatically. System changes equipment setpoints at the right volumes, reducing manual intervention and errors.

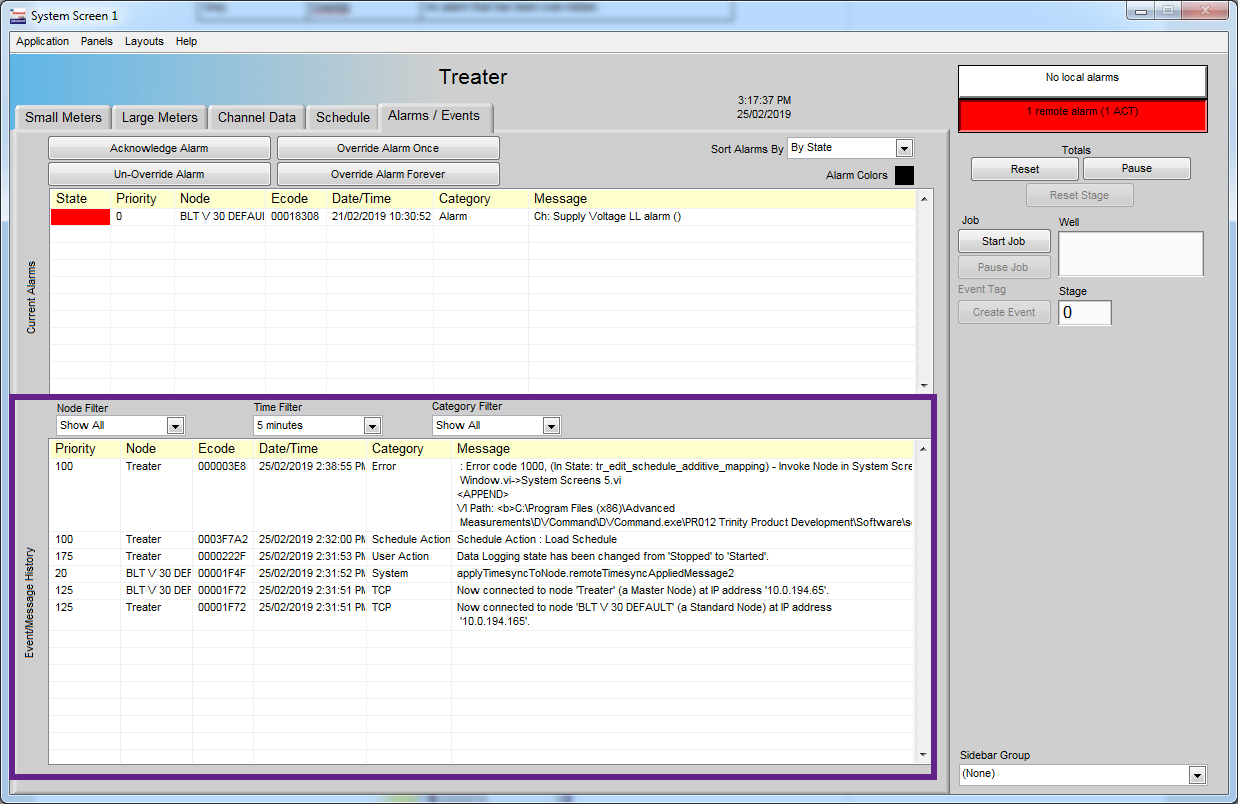

Intelligent Alarms

Multi-level alarm system with configurable priorities. Route critical alarms across the network, acknowledge issues, and maintain a complete event history.

Comprehensive Logging

Continuous data logging for all channels and events. Complete job records with stage totals, equipment status, and operator actions for analysis and documentation.

Real-Time Graphing

Up to 8 channels per graph with unlimited graph windows. Configurable presets, live trending, and export capabilities for documentation and analysis.

Data Export & Reporting

Export to CSV, Excel, or Word. Automated maintenance reports track equipment hours and diagnostics. Complete audit trail for regulatory compliance.

Operational Interface

Purpose-built interface designed for frac operations. Everything operators need is accessible from the main screens.

Operational Advantages

The data van transforms frac operations by providing centralized control, automated execution, and complete visibility. Operators can focus on the job instead of managing individual equipment.

- Reduce operator workload with automated schedule execution

- Respond faster to issues with unified alarm management

- Complete documentation for regulatory compliance and analysis

- Historical playback for post-job analysis and training

- Maintenance tracking reduces downtime and extends equipment life

Network Architecture

Data Collection

Connect blenders, pumps, hydration, chemical systems

Unified Interface

Single command station for all operations

Schedule Control

Automated setpoint management by stage

Data Intelligence

Logging, export, reporting, and analysis

Built for the Field

Agile Automation has designed and delivered multiple data van solutions, handling every aspect from network communications and multi-monitor configuration to sophisticated graphing and reporting systems.

These portable command centers are complex systems—but we engineer them to be simple and intuitive for operators. That's the advantage of purpose-built design backed by field experience.

Command Center for Frac Operations

The data van provides the operational visibility, automation, and control needed for efficient frac operations. From schedule execution to comprehensive logging, it's the central nervous system that ties everything together.

Discuss Your Requirements