Job & Test Management

Organize data by ticket ID with test sets and individual test names. Store job details, customer logos, job types, descriptions, and complete test metadata in database.

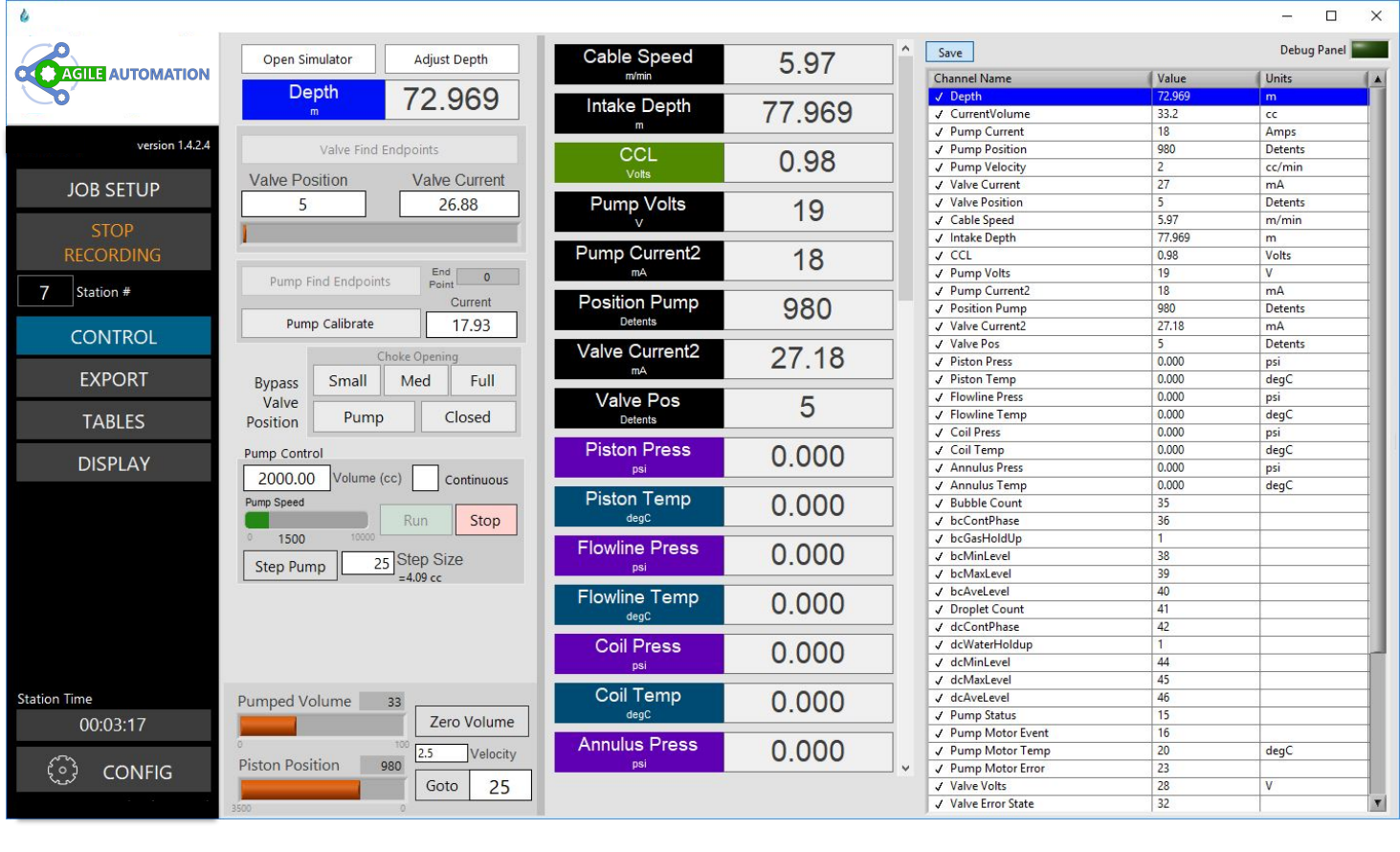

Sophisticated control system for downhole tool testing, calibration, and field operations. Real-time monitoring, intelligent interlocks, comprehensive data logging, and automated reporting—all in a modern, intuitive interface.

Intelligent Interlocks

Prevent unsafe operations

Real-Time Control

Instant status verification

Auto Recovery

Retry logic & error handling

This system was built based on the client's years of field experience testing and operating downhole tools. Every feature addresses real operational challenges—from eliminating command queuing confusion to ensuring emergency stops work instantly.

The result is a robust platform that gives operators complete control, real-time feedback, and comprehensive data logging with the safety interlocks and automation needed for professional tool operations.

Advanced command system with state verification and automatic retry logic. No more command queuing confusion or half-second delays on critical stops. Every operation is validated before execution with real-time status monitoring.

Comprehensive interlock system protects tools and prevents operator errors. Every command validates system state, tool position, and motor status before execution. No more accidentally running commands at the wrong time.

System must be in Ready state. Both valve and pump motors must be Ready, Uncalibrated, or OK before calibration can begin.

Packer and Cutter operations require valve to be in closed position. Pump operations only allowed from Gator or Packer positions.

All pump and valve movements verify motor is in Ready state before sending commands. Real-time monitoring detects non-running states with error popups.

Automated endpoint detection with motion verification, 2-minute timeout protection, and automatic long status query to capture end positions.

System prevents multiple command routines from running simultaneously. Cannot run pump while finding valve ends, or vice versa.

Built-in retry logic with intelligent timeouts. Calibration offers retry after 5s, stops after 1s, movement commands after 2s. All retries logged to database.

Real-time motor controller status with 24 distinct states. System continuously monitors both pump and valve motors, providing instant feedback on operational state, errors, and warnings.

Organize data by ticket ID with test sets and individual test names. Store job details, customer logos, job types, descriptions, and complete test metadata in database.

Map any channel to any data source. Configure units (metric, imperial, mixed), scaling, offsets, and filtering. Support for multiple hardware interfaces and calculated channels.

Live trending with customizable graph presets. Save axis settings, colors, line styles, plot ranges. Apply presets to multiple graphs. Export screenshots for documentation.

Configurable grid for up to 16 live data displays. Select any channels from configuration, uses channel colors and precision settings. Purpose-built for monitoring live data.

System supports multiple tool types with unique configurations. Store tool descriptions, calibration data, sensor information, and serial numbers in tool library.

Each tool connection has hardware-specific settings—piston limits, sensor ranges, config parameters. Calculated channels available for derived measurements. Future support for WITS and additional protocols.

Hardware interface selection, sensor setup, calibration parameters, and operational limits stored per tool.

All available channels from all data sources accessible for mapping. Scale, offset, and filter per channel.

Store unlimited tools with descriptions, serial numbers, calibration notes, and complete configuration history.

Every feature in this system addresses actual field challenges. The command improvements eliminate the confusion and delays seen in previous systems. Safety interlocks prevent operator errors. Automatic retry logic handles communication hiccups without user intervention.

This isn't theoretical—it's proven in the field, refined through real use, and built to handle the demands of professional downhole tool operations.

Command Layer

State verification, interlocks, retry logic

Data Acquisition

Multi-source channels, real-time logging

Visualization

Live meters, trending, playback

Reporting

CSV exports, Word templates, customer branding

This system represents years of field experience refined into a robust platform for downhole tool testing and operations. Intelligent interlocks, real-time monitoring, comprehensive data logging, and professional reporting—all designed to make operations safer, faster, and more reliable.

Discuss Your Requirements