Dual Environment Control

Seamlessly operate from both data van and blender locations. Switch between viewing and control modes with clear visual indicators and automatic controller handoff.

Custom standalone web application designed for data van and blender environments. Integrates seamlessly with existing equipment while providing independent control, synchronization, and offline capability.

Seamlessly operate from both data van and blender locations. Switch between viewing and control modes with clear visual indicators and automatic controller handoff.

Real-time data synchronization between assets using MQTT. Share materials, schedules, and execution history across your operation with reliable message delivery.

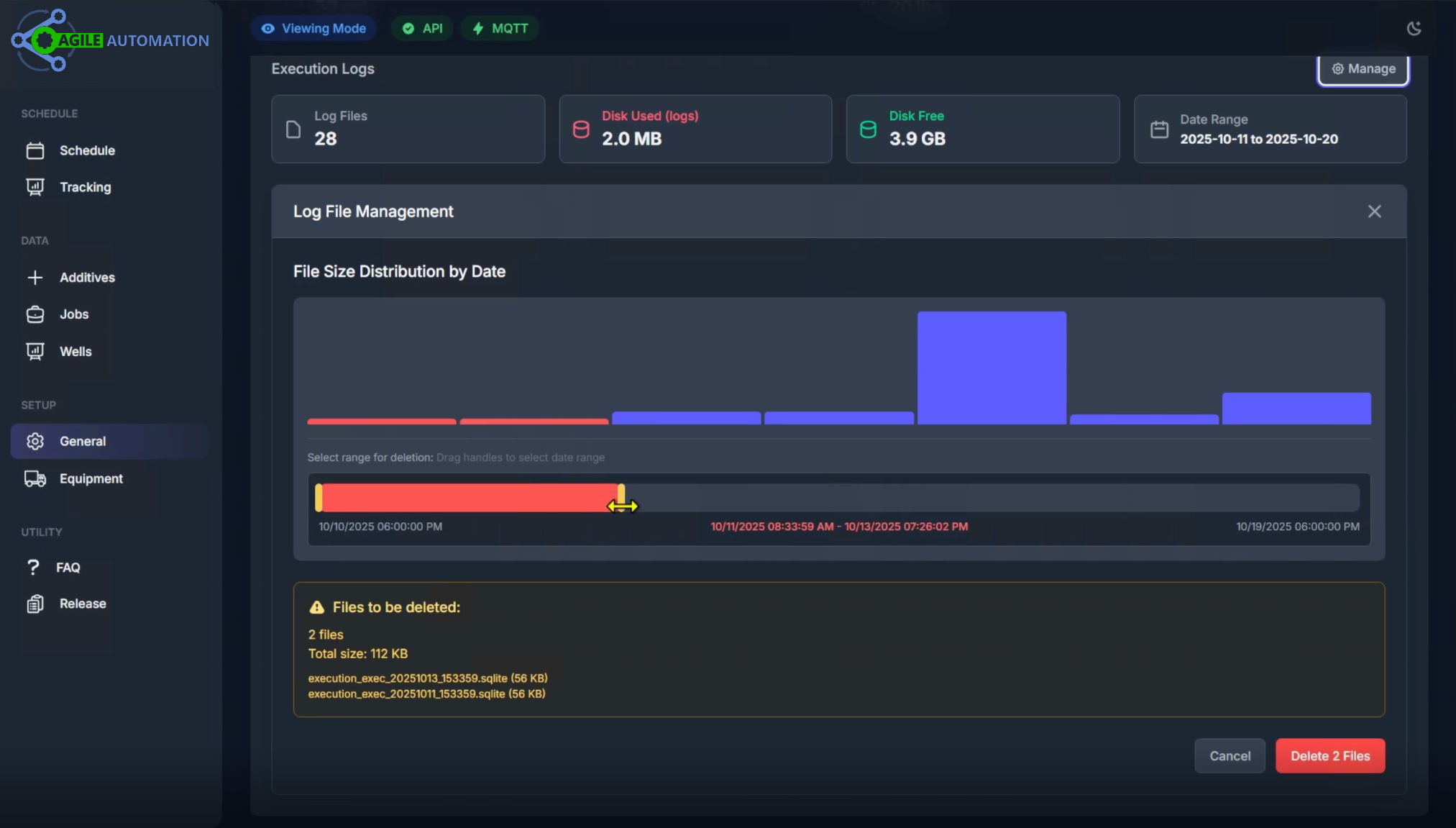

Full functionality without internet connectivity. All data stored locally with SQLite databases, ensuring operations continue in any environment.

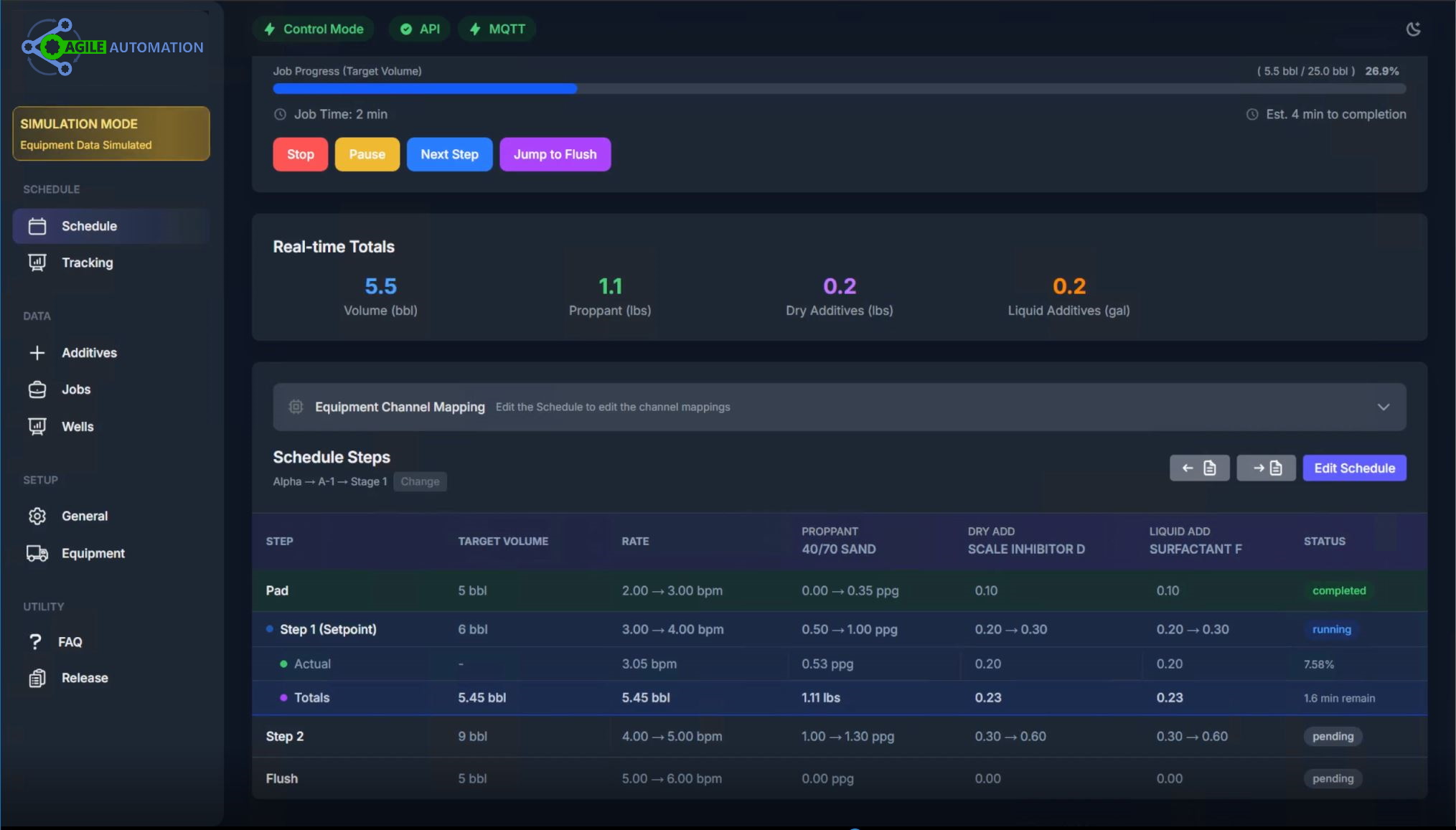

Live tracking of volumes, concentrations, and additive rates. Auto-advancing based on pump target volumes with progress bars and time estimates.

Build, edit, and execute complex pumping schedules with precision. Support for unlimited stages and steps with concentration and additive ramping.

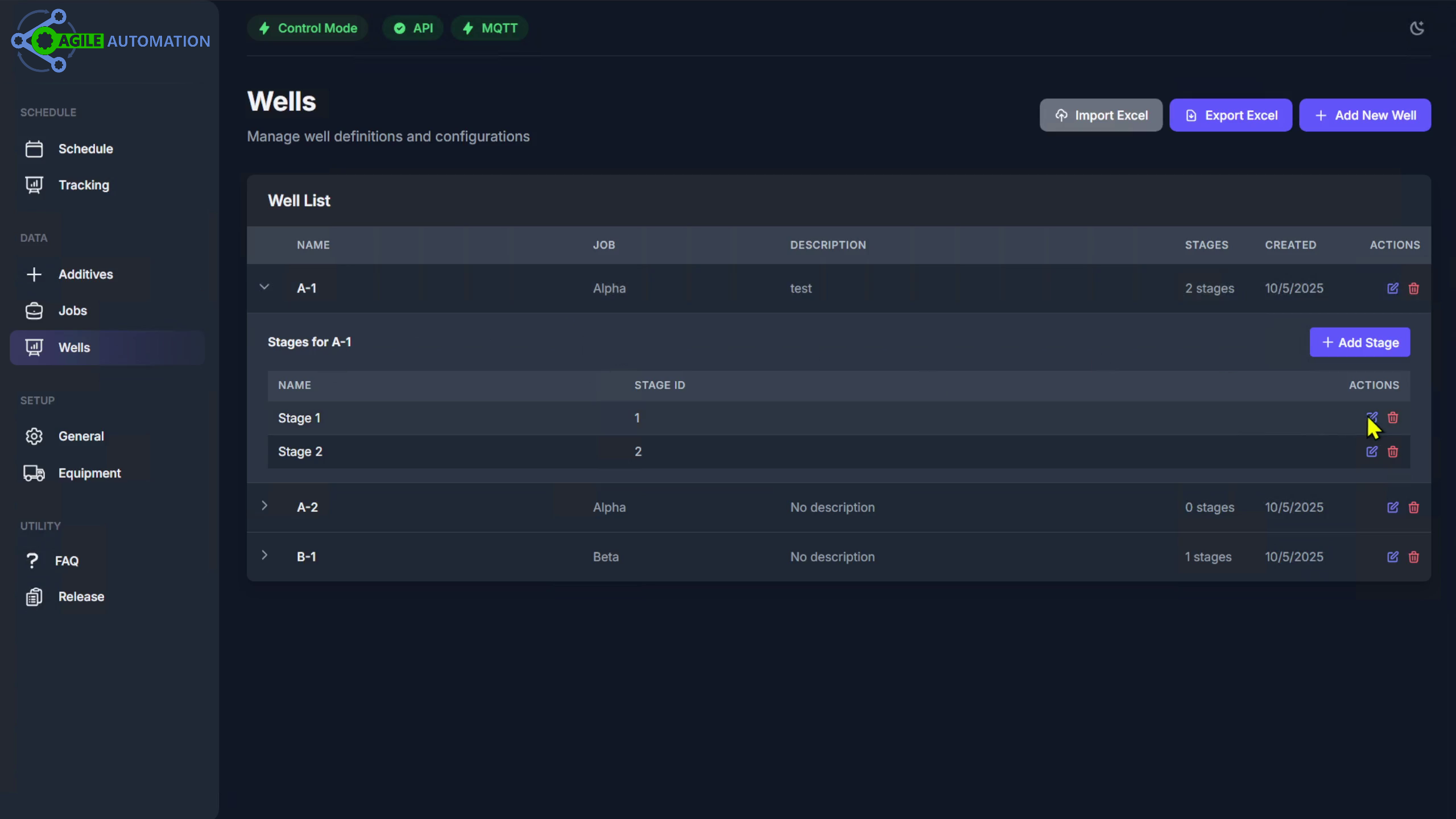

Hierarchical organization of jobs, wells, and stages. Quick navigation and selection with breadcrumb interface for efficient workflow.

Import and export schedules, materials, and job data with Excel templates. Historical execution logs stored per-stage for complete audit trails.

Centralized management of proppants, dry additives, and liquid additives with specific gravity and bulk density tracking.

Map your schedule materials to hardware channels with live MQTT data ingestion. Visual validation ensures all materials are properly assigned before execution.

Full operational control with comprehensive logging for audit, analysis, and continuous improvement.

Temporarily halt execution

Jump steps or stages

Immediate flush state

Live cumulative tracking

Each stage execution creates a dedicated database file capturing live data snapshots, step-by-step actuals, running totals, and the immutable schedule setup. Files include execution markers and follow standardized naming conventions for easy audit and analysis.

This standalone web application was custom-built to integrate data with existing Danfoss controllers and field equipment. Modern control interface with offline capability, real-time MQTT synchronization, and comprehensive logging—all while working alongside your current systems.

Discuss Your Project